Along with the increasing the installed capacity of thermal power unit, the generator capacity has expanded from 300 MW to 600 MW, 1000 MW, for generator stator end design, improvement and test of dynamic characteristics research already have a certain scale, especially the use of all kinds of new test means of generator winding ends method for natural frequency and modal test analysis is more and more mature.Generator stator winding end is the most weak part, the safe operation of the generator stator end windings involute part of the irregular shape decided it can't be as strong as slot line bar fixed, due to the manufacturing process problems, many block and just point contact between bars, cannot form a rigid structure.Formed in the operation of the two kinds of frequency of vibration effect, one is the frequency effect, vibration frequency and speed;Another kind is by the line of the stator winding of the stator core and rotor magnetic field caused by The Times on the rod vibration frequency (100 Hz), by double radial power frequency of the alternating force effect, the direct ratio with the current of secondary.Stator winding end resonant bands or to other causes, bracket bolts and fasteners loose groove and bar insulation wear phenomenon occurs frequently, make frequent accident generator.So the accurate measurement of the stator winding end, the vibration characteristics prediction generator, the vibration characteristics in the actual work condition as soon as possible to take preventive measures is particularly important.Application MYG suite of power tools and power tools and state analysis and hammering state were analyzed, and the evaluation of overall structure dynamic characteristic of generator winding ends, is in recent years developed a kind of effective method.

Modal is the inherent vibration characteristics of mechanical structure. Each mode has a specific natural frequency, damping ratio and modal vibration mode. Through the modal analysis, grasps the structure at a particular frequency range all orders of main modal characteristics, can be expected to actual vibration response in the structure at this stage. Modal test is measured by the natural frequency of each part with computational tools and configuration software in mathematical method to determine the overall natural frequency and vibration under different frequency form. Through the stator winding end test natural frequency and modal analysis test, to determine the dynamic characteristics of generator stator winding end, confirmation of the stator winding end if there is a 95 hz ~ 110 hz range of the natural frequency and vibration type mode; Measuring the inherent frequency of the wire at the same time, confirm whether there is a 95 hz ~ 108 hz range of frequencies.

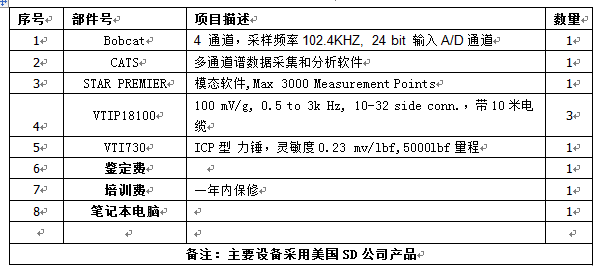

MYG power tools and state analysis and hammer suite configuration list

MYG发电机模态分析及锤击套件配置清单

现场测试图片: